Protect Your Heating System with the Right Water

At Asensi, we bring Elysator’s proven water treatment technology to Finland. We help you protect heating and cooling systems from corrosion, scale, and failure.

Whether you’re installing a new system, maintaining an old one, or simply topping up, we guide you to the right solution.

SWISS

MADE

Analysing the heating water on a regular basis is the first step towards ensuring that the heating system operates faultlessly.

The PUROTAP® EC-18 tests conductivity, salts and salt concentration, with automatic temperature compensation (ATC)

Not all water

is the same.

Plain drinking water may be healthy for you, but it’s capable of damaging your heating and cooling systems.

Untreated tap water contains minerals (like calcium and magnesium), dissolved salts, gases (like oxygen and carbon dioxide), and other substances capable of causing these conditions:

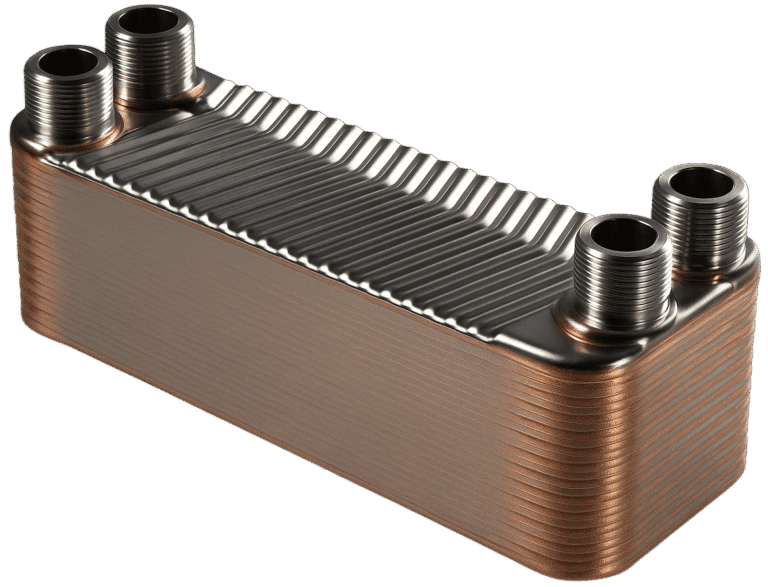

- Limescale build-up on heat exchangers

- Trigger corrosion in pipes, pumps, manifolds and other critical system parts

- Reduction of system efficiency and increased energy use

- Voiding the manufacturer warranty on many heating and cooling systems and their parts

What makes technical water different from tap water?

Quick facts

Drinking Water

Technical Water

Rich in minerals

Low conductivity

Contains oxygen

Oxygen removed or controlled

pH varies

pH optimized

May damage metals

Safe for all materials

The reasons for modern technical guidelines to exist, such as VDI 2035, SWKI BT 102-1 and ÖNORM H5195-1.

These require closed-loop system water quality to be monitored and treated to achieve the intended system life time and performance.

The VDI 2035 standard

Make sure your conductivity is below 1500 µS for sealed systems and below 100 µS for open vent systems and systems with air ingress potential

The pH level influences how corrosive water is to different metals. If the pH is too low (acidic), it will corrode metals. On the other hand, excessively high pH (alkaline water) can damage materials such as aluminum and rubber seals.

Recommendation: For systems with steel components, the pH should be maintained between 8.2 and 10.0. If the system includes aluminium components, the recommended range is a stricter 8.2 to 9.0.

In most domestic systems the scale level should be below 300 ppm for a boiler and approaching 200 ppm minimum for systems with a heat pump

Reduce the oxygen levels. VDI suggests that most scaled systems will settle to a value of 0,02 mg/l where no additional measures are required beyond this level.

The VDI 2035 standard is about preventing problems in heating and cooling systems, not just fixing them.

By controlling the water quality, we stop corrosion and damage before they can begin. Systems that follow VDI 2035 have proven benefits:

- Fewer breakdowns

- Improved energy efficiency

- Longer equipment lifespan

The VDI 2035 standard is about preventing problems in heating and cooling systems, not just fixing them.

By controlling the water quality, we stop corrosion and damage before they can begin. Systems that follow VDI 2035 have proven benefits:

- Fewer breakdowns

- Improved energy efficiency

- Longer equipment lifespan

Many manufacturers require VDI 2035 for their installation and warranty terms. In Finland, these guidelines are already in place for products like geothermal heat pumps and are expected to become a controlled requirement.

Explore your water quality, VDI and corrosion effects

Consequences of having inappropriate water quality

Air in The System?

What it does to your system:

- Sludge formation that accumulate in the pipes or radiators or worse, heat exchangers and control valves

- Abrasive sludge can damage mechanical components such as pumps and valves

- Reduction of efficiency as air acts as an insulation

- Air causes sound and noise in the system

What VDI recommends:

- Keep dissolved oxygen as low as possible ideally: « 0.1 mg /l (0.02 for stainless steel)

- Prevent continuous oxygen ingress: ensure the system is tightly sealed and use oxygen barrier pipes

Impurities and Debris?

What it does to your system:

- High concentrations of dissolved salt (especially chlorides and sulfates) increase the conductivity leading to increase corrosion

- Scale formation: hardness forming minerals (calcium and magnesium) precipitate at high temp forming limescale: typical for heat exchangers, boiler, and heat pumps).

Causes wearing or even worse, blockage in the narrow passages of heat exchangers, pipes. Similar to air, it also contributes to wearing with abrasive debris.

What VDI recommends:

- Control hardness: Water hardness should be kept very low, typically <0.02 mol/m3 (equivalent to <0.3°dH or <0.5°dH )

- Demineralization: use demineralised water (ion exchange or reverse osmosis treated) for initial filling or top ups to remove dissolved salts

- Minimize the conductivity (see corrosion tab)

Inappropriate pH value?

What it does to your system:

- Low pH (acidic water) is highly corrosive to most common metals on heating systems, dissolving protective oxide layers

- An optimal Ph value enables the formation of a Protective Layer

- Very high pH (strong alkaline water) can be corrosive particular to aluminium or zinc compoments or even rubber gasket/O-rings as it dissolves their amphoteric oxide layers

What VDI recommends:

- For system without aluminium components : pH range of 8.2 to 10.0 (optimum 8.5-9.5)

- For system with aluminium components or aluminium alloy: tighter range of 8.2 to 9.0 (sometimes 8.5)

- Self alkalinization: in demineralised and oxygen free systems, the pH often naturally rises in the recommended alkaline range (e.g.through reaction of steel with water or using using system as Elysator)

Explore your water quality, VDI and corrosion effects

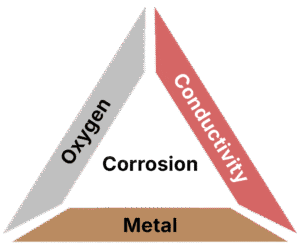

Understanding the mechanism of corrosion in heating systems:

Corrosion is in heating is primarily an electrochemical process where metals reverts to a more stable , oxidised form like rust. It short it is a slow continuous “eating away” of the metal. For this process to occur it require typically 3 elements:

- An anode: the area of the metal that corrodes (loses electron and becomes oxidised)

- A cathode: the area of the metal where a reduction occurs (gains electron and, often involving oxygen)

- An electrolyte the water in the system which must be able to conduct electricity (contains dissolved ions) The higher the concentration of ions the more conductivity and the faster the electrochemical reaction proceed/occurs.

When these conditions are met, an electrochemical cell is formed.

This leads to the transfer of electrons with the outcome of breaking down the metal